Digital Label Press /

Card Personalization

Digital Label Press

The Buskro DLP125-M is a fully integrated, servo driven digital label press which combines Buskro’s proven inkjet and control software…

Read More

Buskro’s Card Personalization System

Buskro’s Card Personalization System or CPS, is the latest addition to Buskro’s complete line of variable digital printing and material handling solutions….

Read More

Digital Label Press

Variable Data, High Speed/High Quality Inkjet Label Printing System

The Buskro DLP125-M is a fully integrated, servo driven digital label press which combines Buskro’s proven inkjet and control software capabilities with over 40 years of mechanical and material handling experience to create a simple yet powerful variable

We cannot display this gallery

Portable, Precise, Proven Technology

The DLP125-M is designed to accommodate labels up to 125mm wide with a maximum roll diameter of 482mm on a standard 76mm core, Operating at speeds up to 60m/min. Incorporating all elements. It incorporates all elements of a digital production label printing system in a compact integrated package with user-friendly job management through simple touchpad web controls and intuitive Compose software making it perfect for production runs of all sizes. All critical elements from the precise servo-driven web drive system to the variable print control and piezo inkjet printing engine have been engineered to provide an efficient, fast, and reliable print solution intended for late-stage, near-line label personalisation.

Inkjet Printing

The DLP125-M comes equipped with a fully integrated Quantum 4260 printer which seamlessly integrates on the printing platform of the label press and includes a convenient automated maintenance and park station to deliver optimal print reliability and performance. The Quantum print unit provides a 4.25” (108mm) vertical print swath and produces high-speed, high-quality label images at resolutions up to 600 x 1200 DPI. The DLP125-M can achieve printing speeds of up to 70,000 – 2” (76mm) labels per hour and with UV-curable and Security inks can print on the majority of common label substrates.

Compose Software

Buskro’s established industry leading Compose IQ Software provides powerful system controls and data manipulation elements, while its user-friendly interface delivers intuitive tools for fast and easy list importation, job preparation, job storage, production audit reporting and system archiving with real-time information being generated during system operations. Add on cameras or other reading devices for more sophisticated matching operations, verification and preparation of audit files.

Features:

- Supports 4.25” (108mm) wide print up to 600 x 1200 DPI resolution

- Simple media path with Unwind/ rewind servo web-drive at speeds up to 100 cm/s

- UV-curable black and security ink formulations for printing on the most challenging substrates

- Fully integrated inkjet printer includes automated maintenance and LED curing lamp

- Media rolls from ½” (13mm) to 5” (127mm) wide and up to 19” (483mm) diameter with standard 3” core

- Quick job change-over with simple media roll installation and software job management

- Touch screen with remote production monitoring

- Advanced optional capabilities include: read/print, label position tracking, RFID/print matching, camera inspection/verification, waste management

- Compose IQ supports fixed and variable text, 1D, 2D and QR Barcodes, as well as common Packaging Barcodes including GS1, Harvest Mark, GTIN, UPC and EAN

- Record searching, reprinting, duplicate print lockout

- Buskro’s fully integrated contactless RFID solution allows you to read & encode (UID) information onto a variety of formats, including LF, HF and UHF, assign variable data and provide audit files with appended data

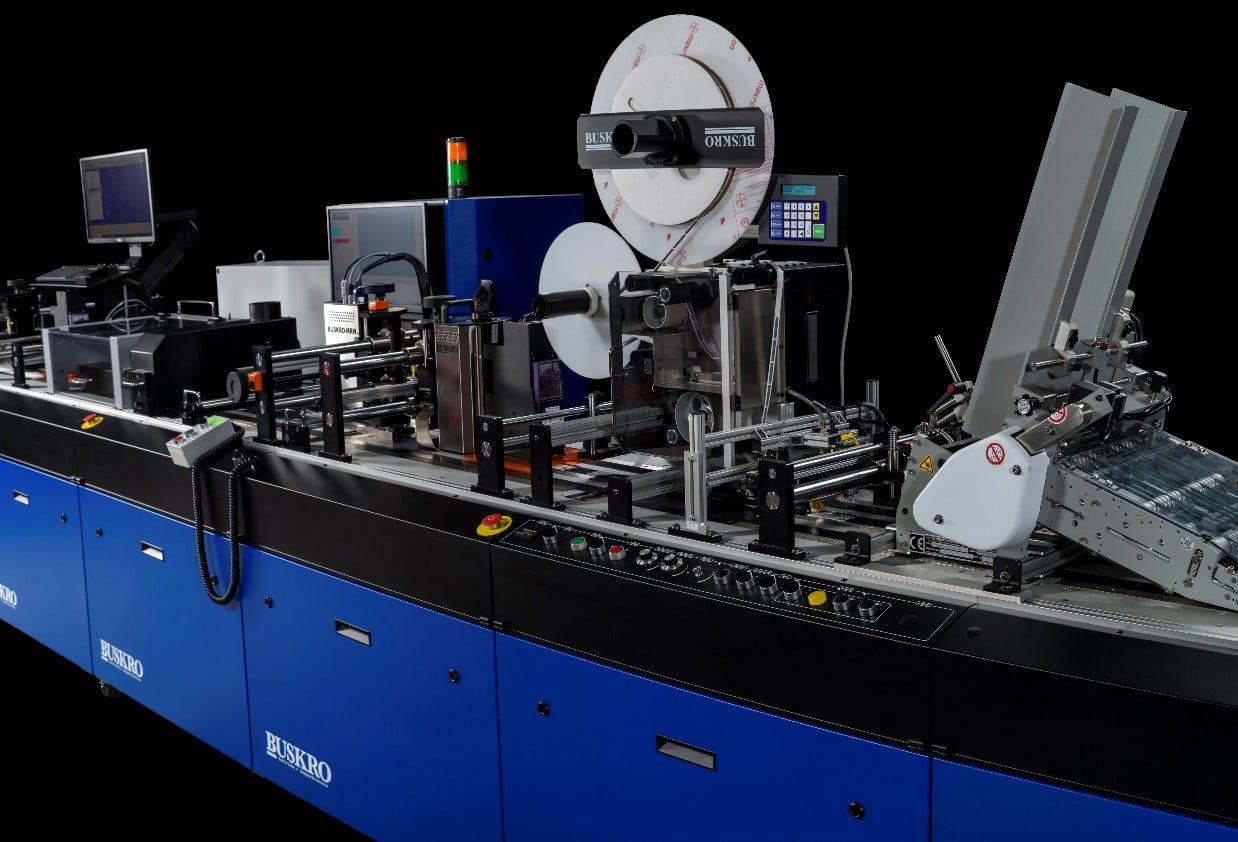

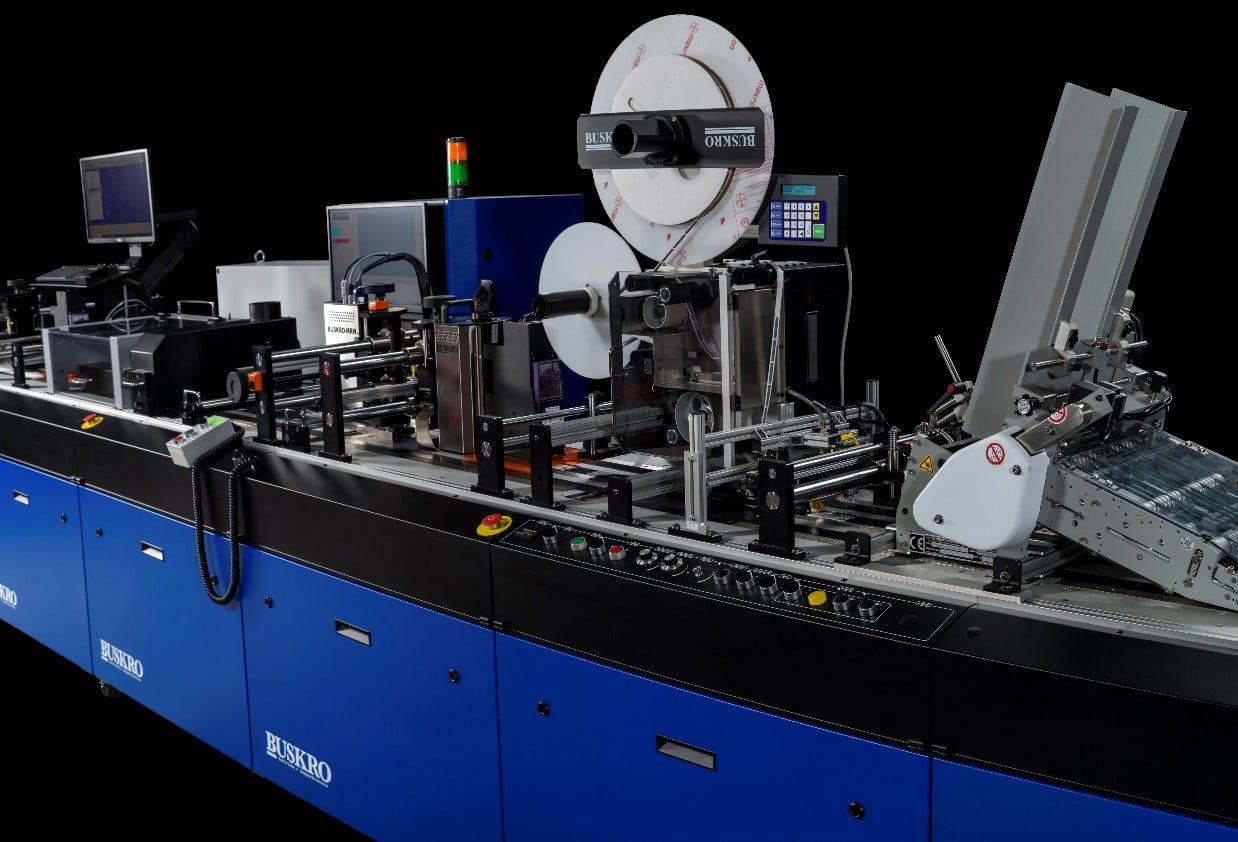

Buskro’s Card Personalization System

Buskro’s Card Personalization System or CPS, is the latest addition to Buskro’s complete line of variable digital printing and material handling solutions.

The CPS is a fully-integrated, purpose-built solution, designed specifically for the plastic card personalization industry. Compose IQ, the driving force behind the CPS has been developed over the last 25 years to allow for inkjet print, mag stripe encoding and verification to be housed all in one controller. Compose IQ, the driving force behind the CPS, has been developed over the last 25 plus years. Compose IQ has been engineered with a strict focus on real-time data management and integrity, and allows us to fully and seamlessly integrate all elements of the system. Buskro’s in-house design approach and modular system architecture allows us to offer a fully-featured card personalization system at a very competitive price point.

The CPS is comprised of four main elements: Buskro’s powerful and proven Compose IQ software package; our complete family of inkjet printing solutions; our most recent innovations;

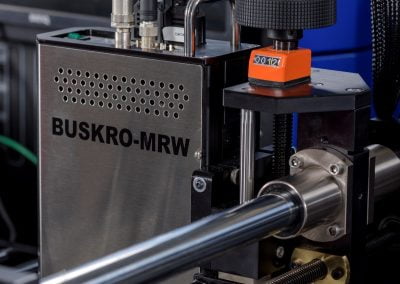

- Buskro’s MRW high-speed

- Magnetic

- Stripe writing and verification unit

- The modular MTS transport system

You can choose from the complete range of Buskro’s inkjet print solutions to configure the system that best suits your needs. Our 2500 and 5100 series print heads can be configured with solvent or UV curable inks and are available in 65 millimeter (2.55”) and 150 millimeter (5.1”) print swaths. The Buskro 2500 CGS print head offers high quality CMYK UV print on a wide variety of substrates including plastics and metal. Buskro also offers both LED and traditional mercury lamp curing options to suit any UV print application.

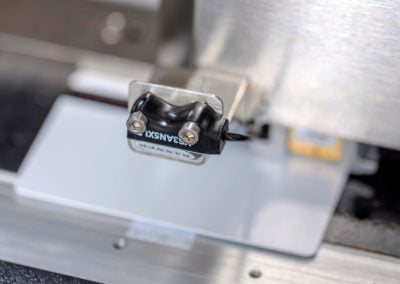

The most recent development of the CPS is Buskro’s MRW magnetic stripe encode/decode module. The MRW was engineered to seamlessly integrate with Buskro’s system architecture. Designed and tested to meet the latest ISO standards, the MRW offers encoding on up to three tracks at speeds in excess of 20,000 cards per hour. Precision adjustments and powerful diagnostic tools make set up and adjustments simple and concise. The interface in Compose IQ allows the user to toggle between tracks, select bit densities and assign the appropriate data quickly and easily, creating a superior user experience.

The Modular Transport System (MTS) is a rugged, purpose-built transport system, specifically engineered for the card personalization market. The flexible, modular design allows us to configure the system in virtually any size to suit your specific application and footprint requirements. The MTS offers a variety of optional components including precision print platforms, curing or drying modules, labelling heads, turnover devices and divert bins. The MTS features a simple, yet sophisticated drive system that makes it easy to expand the system as your requirements change ensuring your investment will continue to pay dividends for many years to come.

Buskro’s Compose IQ software is the driving force behind the CPS. Compose IQ allows us to fully and seamlessly integrate all elements of the system. Compose IQ communicates directly with all aspects of the system through a single PC and software interface. All functions of the line are closely monitored and each product is tracked in real time without data buffering. Compose IQ can interface with a variety of barcode verification and vision products, and can provide an audit of all recorded events, providing full system integrity. Any unverified or waste products are logged and placed in a re-order table and reprints can be performed automatically at the end of a defined batch, or at the end of the production run. User-friendly product layout and diagnostic tools, combined with the ability to save and recall frequently used jobs, help to reduce make-ready time and maximize daily output. Our unique system architecture makes it easy and cost-effective to expand as your needs dictate, by adding additional print capacity, verification options, and other ancillary components.